Road Weigh Bridge | Maxim Weigh

We are aware that a Road Weighbridge is a long-term investment that, with good maintenance, may last over 25 years. Your scale will last longer, require fewer expensive repairs, and eliminate losses due to incorrect weight transactions with routine calibration, inspections, and cleaning. Your cash register is the scale on your truck. A reliable and precise Road Weighbridge is crucial to your business’s growth and profitability since supplies come in and finished goods leave. As your partner for scale installation, operation, and maintenance, you can rely on Quality Scales Unlimited.

Road Weighbridge Solutions

Superior Scales Worldwide offers a large selection of electronic, cutting-edge Road Weighbridges from leading manufacturers, many of which are proudly built in the United States, in common sizes, and with different capacities. Instead of the proprietary load cells that some manufacturers offer, our manufacturers provide a fully electronic design using industry-standard load cells.

Our truck scales, some of the toughest designs in the business, are certified for giving emphasis capacities (CLC) up to 50,000 lbs. and are rated for loads up to 100 ttons Compared to other scales, whose deck weighs closer to 30,000 lbs, our steel-deck support provided about 40,000 lbs of steel. The Road Weighbridges are physically more robust thanks to the additional steel.

The design and functions of Road Weighbridges vary a little bit depending on the manufacturer. We can help you choose the Road Weighbridge that is better suited for your unique needs when you are looking for one and, if necessary, we can help modify the scale to fit your needs.

Some features and customizations include:

- Above or below-ground profiles

- Custom dimensions

- Concrete or steel decks

- Portability frames

- Guide rails

- Manholes

- Corrosion-resistant load cells

- Existing pit and foundation matching

- Extreme weight capacities

- Dump through modules

More peripheral equipment includes:

- Automated ticketing kiosks

- Remote displays, surveillance cameras

- Weight indicators

- Traffic controls

- Ticket printers and more.

How Do Modern Road Weighbridges Work?

Electromechanical and hybrid scales are outfitted with digital strain gauge load cells, a going-to-weigh terminal with a digital weight indicator and operator guidance, as well as connectors for printers, having switched contacts, field bus and network interactions, second displays, and other additional equipment, all of which facilitate a largely automated weighing process in this era of modern industrial growth (Industry 4.0) and the Internet of Things.

Any analog signal to a digital load cell with an RS485 connection can be connected to the WTX110 weighing terminal to be used losslessly as a digital measurement chain. Using the TFT color display, the entire scale was simple to set up on location. The WTX weighing terminal can be networked through an Ethernet interface, allowing for remote parameterization, viewing, and control using the HBM Panel software. Weighing software is therefore necessary for scale operation, and it regulates the whole weighing process through the creation of bills.

Types of weighing machines

Road Weighbridges are typically manual, meaning that someone must operate them. AWIs entirely independently do all weighing activities, including placing and removing the weight, which aids in the automation of industrial production. This kind of scale, however, needs special authorization and is governed by European Directive 2014/32/EC. Axle load gauges are not permitted to measure goods traffic in Germany since they are illegal for commercial use. They are therefore only employed for checking. Most vehicles are weighed on all-in-one Road Weighbridges, which can either be flush with the ground or over the floor mounted.

The history of Road Weighbridges

The rise of industrialization and the associated growth in the movement of large products marks the beginning of the development of Road Weighbridges. Before the 18th century was underway, goods were weighed by hand. The things could not weigh over 500 kg because this job was manual and that was the weight of a typical container in those days.

Since the middle of the 20th century, electronic and hybrid scales have steadily replaced mechanical weighing devices. In truth, Road Weighbridges have used load cells based on gauges (SG) as their technical foundation since the mid-1990s.

Road Weighbridges could be installed on the surface or in a pit. Scales that are surface-mounted are simpler to adjust and are simpler to clean and maintain. However, Road Weighbridges, which are flush with the ground and may also be traversed obliquely, are more resilient to damage and are typically the scales of choice during long-term use in factory facilities.

Road Weighbridges are offered in reinforced concrete or steel. Off-center load correction must be done before the scale is put to use to prevent measurement mistakes. Here, a conformance assessment is carried out after placing reference weights on each of the scale’s weighing points. Thereafter, up until the maximum load, the scales are gradually subjected to increasing amounts of weight. In the ensuing procedure, this reduces scale measurement inaccuracies brought on by one-sided loading.

Using Road Weighbridges

Road Weighbridge operation can be done in a variety of ways. The car is first driven up to the scale. Afterward, the driver can start the self-weighing process using the operator’s terminal or controller cabinet. The linking of a weighing procedure with an order and preventing unauthorized manipulation are both possible using a variety of identifying techniques (such as a smartphone or barcode). Additionally, utilizing camera and/or sensor-based position tracking, the vehicle license plate is captured and associated with an order. With huge displays that are activated by encrypted data transfer, for example, it is now also feasible to remotely control weights from an office building.

Methods of measurement

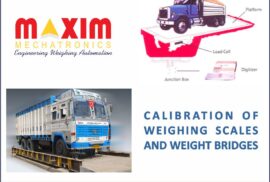

Weight is measured using load cells like the RTN or C16i from HBK in contemporary Road Weighbridges. These digital or analog load cells must meet certain fundamental requirements and be installed by the applicable European Union regulations to be used legally for commercial purposes (WELMEC 2.4). Most often, strain gauge loads are employed. The load cell, which functions as a spring element, deforms when a load is applied, resulting in an electronically quantifiable resistance change on the strain gauge of the load cell. This is sent to electronic devices like weighing terminals where it is processed and displayed as a weight number.

Digital load cells, which permit translation to a digital signal in the real cell, are extensively used today. This is accomplished by integrating a tiny amplifier board within the load cell, which is then sealed up. At the load cell itself, the amplifier subsequently transforms the analog strain gauge signal into the digital one that is significantly less noise-sensitive. As a result, interference caused by factors influencing measurement channels is eliminated, and the sensor signal is also largely protected against manipulation.

Portable Road Weighbridges

Portable Road Weighbridges are available from numerous domestic manufacturers through Quality Scales Unlimited. The portable truck weights we provide are designed for trade applications that call for ease of transportation from job to project. These low-key scales can be customized to your company’s needs and are made to be simple to disassemble and reassemble.

For contractors operating in various locations or on short-term projects that need portability, dependability, robust construction, and verified weights, portable Road Weighbridges are a fantastic solution.

The mobile Road Weighbridges we provide are built with more steel than our rivals and are made with closely spaced broad flange I-beams. The added steel creates a sturdy weighbridge design by increasing durability and support. We provide portable Road Weighbridges that can operate for decades without developing wear and tear.

The Survivor ATV portable Road Weighbridge is made by Rice Lake Weighing Systems and has all the advantages of lifespan, consistency, and toughness of their Survivor series of Road Weighbridges. Because of their high-duty steel design, sturdy weighbridge construction strategically placed I beam, and exceptional quality of finishes and construction, QSU endorses the Rice Lake Survivor series of Road Weighbridge products.