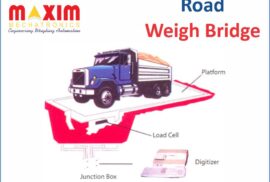

Calibration of weighing scales and weight bridges

Maxim weigh performs weighbridge calibrations by the Calibration Code of Practice for Non-Automatic Weighing Machines published by the UK Weighing Federation, which outlines the exact legal requirements for the calibration of weighbridges and scales that are appropriate for use in commerce.

The following variables affect your weighbridge’s accuracy and performance:

- Construction quality and mechanical design of the weighbridge structure.

- Critical component quality standards include load cells, mounting hardware, and instrumentation.

Whether the calibrating process is effective

The optimal time to calibrate your weighbridge is once every 12 months, although this is not always possible. Trade weighbridge owners are required by law to keep their weighbridges operating within permissible limits. Failing to do so may result in legal action and fines; trading standards have the authority to shut down weighbridges that violate the rules.

- We run specialized weighbridge test units around the UK and are credited for the initial verification and re-qualification of weighbridges as stated in our Module D Certificate provided by our Authorized Body NMO. To calibrate the weighbridge, UKAS traceable weights must be applied to it in a specific way. Tests are run to confirm and determine:

- Zero point

- Maximum capacity (Span)

- Linearity and Hysteresis

- Eccentric error (corner loading)

It’s crucial to keep in mind that whenever you replace crucial (authorized) components like load cells or instrumentation, your weighbridge must be re-tested (re-verified). Any replacement load cells for a certain weighbridge design or manufacturer must have approval from the appropriate authorities.

Additionally keep in mind that improper weighing can result in unintentional vehicle overloading, which exposes you to legal liability.

The Need for Weighbridge Calibration

It really ought to go without saying, but if your company needs a weighbridge; you need to be sure that the measures it provides you with are precise and trustworthy. Without it, you can unknowingly be giving away profitable goods and opening yourself up to legal action.

You might be shocked to learn how many people appear to believe that their weighbridge doesn’t need to be periodically calibrated to make sure it’s still operating properly after it’s been delivered and installed.

No matter how well a piece of machinery is initially designed and built, it will nearly always need some amount of routine maintenance and an annual health check.

What is Weighbridge Calibration?

Simply said, calibration is the process of comparing a measuring device’s performance to a standard with known or traceable accuracy. While calibrating a customer’s weighbridge, we apply load in a predetermined manner using one of our sets of UKAS traceable weights (UKAS is the National Accreditation Body for the UK).

We can rapidly ascertain whether the weighbridge is operating within the exact parameters set forth by law by comparing the stated weight readings to our established standards.

How to calibrate a load cell?

While load cells are precise, they are prone to wear and tear from constant use, which can result in false values. After the system is unloaded, the weight indicator must return to zero for the load cell system to function effectively.

Also, even if the load’s location changes, the system should still be able to display the same weight (uneven loading). The load cells need to be re-calibrated if your load cell system is not exhibiting these symptoms. There are several tests you may run to see if your load cell system is malfunctioning. They include mechanical examination, zero balance testing, bridge testing for resistance, and ground testing for resistance.

Setting up the instrument in a stable environment is the first stage in load cell calibration for a weighing scale. Finally, modify the settings in your load cell’s calibration mode. Span Calibration is typically an available option. Choose this to calibrate the load cell and apply a test load. Press Enter to complete the calibration process after allowing the load cell to adjust.

Calibrating weighing scales and instruments

1. Preparations before calibration

Before beginning the calibration of the weighing device, you should make a few clarifications and gather your supplies.

You should learn about the weighing instrument’s technical specifications (maximum weight, d value), the accuracy standard (maximum error allowed, uncertainty), and what to do in the event the calibration fails (adjustment).

In most cases, the calibration is done where the equipment is being used, covering the entire measurement range. Make sure you have adequate weights on hand to complete the calibration process.

At least 30 minutes before the calibration, turn on the weighing device. The mercury of the kilos should be maintained at the desired calibration temperature. Particularly for compact and precise weighing equipment, the weighing device should be at a level line. Place some weights on the instrument that are close to the range’s maximum for a few pre-tests to make sure it functions normally. You should perform an “as found” calibration before to adjustment and an “as left” calibration following the adjustment if the weighing equipment experiences calibration failure. Let’s now look at the many tests that ought to be performed during the calibration.

2. Eccentricity test

The weight is not always exactly centered on the load receptor during routine usage of a weighing device. If the weight is positioned differently on the load receptor, the findings of a weighing instrument may occasionally fluctuate slightly. The eccentric test is carried out to determine how big of an impact the placement of the load has.

The reference load is applied to the load receptor at several different predetermined sites throughout the eccentricity test. To see the outcome, the load is first positioned at the load receptor’s center of gravity. The load is then positioned in the load receptor’s four separate sectors, as seen in the image below.

In reality, there are many various types of load receptor forms, and the load’s placement will change. The image above shows rectangular and circular load receptors. The OIML R76 and EN 45501 standards will provide direction for various load receptor shapes.

The calibration technique should define where to place the load during the testing and calibration findings (in certification format) should also document the locations.

At least one-third (1/3) of the maximum load of the weighing instrument should be utilized as the test load during an eccentricity test. If at all possible, the test ought to be run with just one test load. This makes it simpler to verify that the load’s center of gravity is where it should be. The highest range should be used for the eccentricity test when a weighing device has numerous ranges.

It is not required to use an exact calibrated load because the eccentricity test’s goal is to determine the difference brought on by the load’s placement. Hence, it’s crucial to maintain the same load throughout the test.

A calibrated load must be utilized if the eccentricity test is also used to identify the indication’s inaccuracies.

How to conduct the eccentricity test

Before running the test, the indicator is zeroed. Placement of the test load at position 1 and recording of the indication. The test load is then moved to positions 2 through 5, where each location’s indication is recorded. To ensure that the indication has not changed from the initial indication at site 1, the test load is placed there once more.

The zero can be checked to make sure it hasn’t changed between each place. Between each test, the device can be zeroed if necessary. To make it simpler to see any differences between locations, you can additionally tare the instrument with the load in location.

3. Repeatability test

The reproducibility of weighing equipment might be problematic, just like with any other instrument. This implies that the outcome is not consistently the same when the identical load is assessed multiple times. A repetition test is conducted to determine the instrument’s repeatability.

To rule out any eccentricity error, the repeatability test is carried out by repeatedly substituting the same weight on the same location on the load receptor. The test needs to be conducted under consistent, identical, and handling-free settings.

The load applied should be somewhat close to the instrument’s maximum load. A repetition test is frequently conducted with a single load, but it can also be conducted separately with several distinct load values.

As the goal is to determine repeatability, the load need not necessarily be calibrated. If at all possible, only one load should be applied (not several small loads).

A measurement is typically repeated at least five times in a row to perform a repeatability test. It ought to be done at least three times for devices with a high range (more than 100 kg/ 220 lbs).

The instrument is initially zeroed for the repeatability test, after which the load is applied to the load receptor, and the indication is recorded after it’s stabilized. The load is then removed, and the zero indicators are examined and, if necessary, zeroed. The load is then put down once more, and so forth. A load that is near yet above the first range maximum is frequently adequate for a multi-range instrument.

4. Weighing test

The goal of the weighing test is to evaluate the weighing instrument’s accuracy (calibrate) throughout multiple steps with rising and decreasing weight.

The following is the most typical practice: begin by zeroing the sensor with no load applied. Set the first test point’s loads, watch for stability, then note the result. During all of the escalating test points, keep up the load increases. Start lowering the loads through the diminishing test points once the maximum load has been recorded.

The weighing device may occasionally be calibrated using simply increasing or only decreasing loads. It is typical to employ 5 to 10 distinct loads (test points). The maximum load should be quite near to the instrument’s maximum. 10% of the ultimate capacity or the lightest weight typically employed can be the smallest test load.

The assessment points are typically chosen to be evenly spread over the range. For the instrument’s typical usage range, more test points can be used.

For instruments with many ranges, each range needs to be calibrated individually.

Linearity

In a weighing test, employing a variety of sites across the instrument’s measurement range aids in identifying any linearity problems. Because of linearity problems, the device does not measure reliably across the whole range. Even the minimum and full span are accurate; nevertheless, there may be linearity faults, also known as nonlinearity, in the center of the range.

Hysteresis

Whenever a test point is reached with rising or decreasing weight, there is a change in the indication known as hysteresis. You must calibrate the device with fluctuating points to detect any hysteresis problems.

It’s crucial to avoid overshooting or undershooting during a weighing test when increasing or reducing the load. This implies that you must approach every test point with more weight as you increase the load. If you add far too much weight and then take it off, the hysteresis information is lost.

Make sure to approach each spot with decreasing weight while using decreasing points. Careful planning must go into how the test loads will be used to accomplish this.

5. Minimum weight test

Testing for minimum weight is one that is not usually necessary. However, some companies, notably the pharmaceutical industry, need this test.

The goal of the minimal weight test is to identify the least load which may be assessed while still producing accurate measurement findings. The relative reading error often increases as the measured value decreases. Any loads less than the minimal energy should not be measured using the weighing device.

The two primary standards take different approaches to the minimum weight test. Let’s quickly review those:

The US Pharmacopeia (Chapter 41)

The need to define the instrument’s lowest operating range by locating the point where the instrument’s reproducibility (2 times the normal deviation) is 0.10% of reading has taken the role of the minimum to weigh test after recent revisions to the standard. Whilst the standard deviation can, in some situations, be quite modest in practice, the weight requirement to be measured should nevertheless not be less than 820 times the scale interval (d).

Calibration Instructions for EURAMET 18 (Appendix G)

Abides by the rule that you compute the measurement errors for each method is a set and the least usable load is the point in which the variability is still minimal enough to satisfy the standards for the instrument.