industrial weighing solutions | Maxim Weigh

A crucial component of the automation sector is weighing systems. Products can be carefully weighed and their weight can be calculated using contemporary weighing technologies. Uses include sanitary measuring in the food, pharmaceutical, and biotech industries as well as offshore petrochemical applications, weighing in logistics, and automation.

The industrial automation weighing technology must be strong and incredibly accurate. Conventional weighing methods are frequently sensitive to shocks or vibrations, which causes errors and inaccuracies in many automated systems. Digital measurement devices that offer the use of unique capacitive weighing technology are the solution. Given that capacitance systems have a far better tolerance for shocks and overheating and hence produce exact measurement results, this digitizes the entire measurement chain and removes the danger of errors. Digital capacitive cells, weighing modules, and weighing indicators are all part of our selection of weighing systems.

The Importance of Weighing Solutions

It’s crucial to have the right weighing solution, especially for sectors that deal with raw materials. By maintaining supplies in an orderly and methodical workspace using weight-based criteria, accurate weights enable greater operational efficiency. When managing substances wherein item counting is either impractical or impossible, this is extremely helpful.

Industrial weighing scales do not offer a universal fit. For acquiring precise weight in a multitude of situations, Garber Metrology provides a wide range of options.

Application of Weighing Solutions

Many applications call for the usage of weighing solutions. Industrial scales are used for a variety of purposes, including but not restricted to:

BATCHING:

used in conjunction with different controllers to control material transfer and improve batch quality and profitability.

COUNTING:

The best inventory method and verifying product amounts are weighing solutions. This is especially useful in cases where manually counting objects is impractical.

FILLING/DOSING:

Effective weighing solutions can help with the repeatable exact filling of bottles, drums, and vials.

FORMULATION:

In situations where raw materials must be blended in exact proportions, accurate weighing is crucial.

SIMPLE WEIGHING:

It is frequently necessary to take a weight measurement right away. The cost of item storage and shipping is frequently calculated using straightforward weighing systems by the warehouse and packing businesses.

EQUIPMENT CALIBRATION:

In equipment, such as volumetric dispensing devices, weighing can be utilized for traceable calibration.

Types of Industrial Products

Table Top Scales: Manufacturers of load cell-based digital tabletop scales include Maxim Weigh. Compact tabletop scales with zeroing and tarring functions make weighing quick and simple. Tabletop scales are used in the food, pharmacy, and chemical sectors for weighing, sampling, and counter-checking purposes. They range in weight from 1 kg to 30 kg.

Platform Scales: Combining a weighing platform and a weight display indicator makes up a platform scale. Platform scales come in capacities ranging from 10 kg to 5000 kg. The platform type is chosen based on the application and the site’s conditions. For certain weighing applications, low-profile and super duper profiles (platforms of lower heights) are offered. There is a large selection of indication and mounting options.

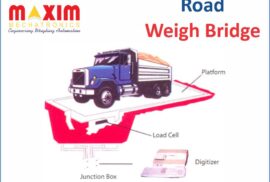

Weigh Bridge: an electronic weighing bridge from Maxim weighs maker. Platform construction, load cells, junction boxes, and weight indicators with PC interface make up the bulk of a weighing bridge. The modular design of weighbridges allows for a wide range of capacities and sizes (30 Ton to 100 Ton).

Filling Systems: optimum weight for filling jars, tins, and drums, a liquid filling system is offered. The filling nozzle, weight controller, and weighing platform make up a drum-filling system. A drum can be filled to a variety of heights. Filling systems are created based on the characteristics of the liquid, such as viscosity, foaming potential, and so on.

Belt Weighing Scales: When concurrent measuring of raw resources and additions on the belt (dynamic weighing) is necessary, products from Maxim weigh Sensors are frequently employed.

Our industrial in-line measuring technology is simple to connect and takes little time to install. The systems require little maintenance and are very well protected against dirt. High precision is provided here for extremely challenging industrial situations.

For speed detection, the devices are furnished with application-specific sensors. The maximum level of precision is achieved by conveyor belt weighing systems.

In-Motion Weighing: Commercial in-motion weighing equipment with a daily output is required by expanding online retail firms. While in the processing facility, packages must be measured dynamically or statically dynamic or static manner.

The weighing platforms will be adjusted by Maxim Weigh Instruments to the sizes and weights of the shipments. A streamlined operation procedure is also made possible by several numbers of interfaces, software protocols, and programmable control devices for transferring data in the customer’s Maxim Weigh. In a nutshell, in-motion weighing scales make shipping much simpler.

Conclusion

To prevent affecting the calibrating accuracy of the system, any environmental conditions like temperature, humidity, or dirt must be monitored and controlled. Also, regular inspections should be carried out to spot any possible issues before they materialize so they can be remedied right away. By following these recommendations, you can help keep commercial weighing scales and systems in top shape and make sure they keep giving accurate results over time. We hope this post has helped you understand the significance of accurate industrial weighing both in logistics and manufacturing. We can assist you whether you require a new scale or just need someone to calibrate your current equipment. For additional information or to begin your project, get in touch with us immediately. We are industry leaders in all things related to industrial weighing.