Analytical Balances | Maxim Weigh

What is an Analytical Balance?

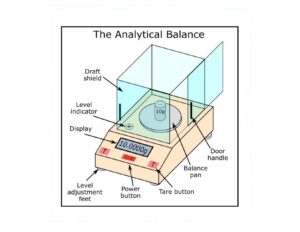

In the field of quantitative chemical analysis, analytical balances are precise measuring tools used to calculate the masses of solids, liquids, powders, and granular particles. The readability of an electronic balance today is up to.0001 g and it operates on the magnetic force restoration concept. High-precision laboratory balances for mass measurement are frequently made with an enclosed measuring pan to reduce the impact of air currents and dust; they may also have choices for vibration resistance, data transfer, automation, and capacity range.

Academic scales or scientific balances classified as analytical balances are used for precise weighing tasks involving small volumes of material in laboratories, classrooms, larger industrial workplaces, or any other setting needing rapid and precise weighing performance. With predetermined weighing ranges, readabilities, accuracy rates, and repeat abilities, a broad variety of models are offered.

Analytical balances are commonly built with weighing capacities ranging from 1 mg to 200 g and readabilities of 0.1 mg to 0.01 mg or better, depending on the model. From 0.1 mg and up, micro-analytical scales are used to weigh much smaller quantities of material.

Analytical balances are frequently used in conjunction with sample containers including calibration weight sets, weighing papers, and special spatulas for handling and transferring samples.

Analytical Balance Features

- Integrated method and data storage, including USB and RS232 connection for data download and communication

- Simple multi-touch user interfaces and clear backlit displays for straightforward operation

- Draught shields with movable tops and doors to shield the measurement pan from airflow

- Overload/underload indicators and level adjustment indicators

- various weighing modes and measuring units

- Functions for internal or external calibration and vehicle

How Are Analytical Balances Used?

- Routine sampling and weighing of chemicals

- Dynamic weighing of erratic items like liquids, insects, or small animals

- counting of little bits, tablets, and other components and objects

- counting of pieces, tablets, or other tiny components

- Density calculations

How often should Analytical Balances be calibrated?

You must consistently check and adjust your analytical balance. Although automatic internal calibration is an option, it is also advised to calibrate the balance using certified external weights. Several influences include.

- Use frequency: Calibration should be performed more frequently for scales that are used weekly compared to balances that are used daily. The balances must be calibrated at least once every day if you use them frequently.

- Use frequency: Calibration should be performed more frequently with a daily-used balance than with weekly-used scales. If the balances are used frequently, they must be calibrated at a minimum every day.

- The significance of the findings of the weighing being accurate.

- the advice of the manufacturer

- After moving, your scale or balance has to be calibrated. Why? Every site in the world is oriented differently to “magnetic north” because gravitation is not the same everywhere on Earth. This causes extremely tiny gravitational variances based on a location’s altitude relative to sea level. As you move your balance (for instance, to a different floor), the balance will show a different value because the force of gravity drawing the mass towards the Earth’s center iris drawing the mass towards the center of the Earth will change.

Industries That Use Analytical Balances

An analytical scale is an essential piece of equipment for any business that depends on quantitative chemical evaluation due to its accurate measurements. They are appropriate for a wide range of industrial applications since they are readily accessible in a variety of sizes and designs and can display readings in different units.

They include manufacturing facilities for chemicals, polymers, food, pharmaceuticals, quality management labs, and calibration labs among others. For weighing samples and reagents for solution preparation, analytical balancing precision and accuracy are crucial regardless of the type of analytical method you apply.

Using an Analytical Balance

- The balance must first be leveled and zeroed before you may weigh your sample. Verify that the leveling bubble on the floor of the weighing chamber is in the middle, or adjust the leveling screws that are situated beneath. Close the chamber doors after that and quickly depress the control bar until a line of zeros appears on the screen.

- By opening the compartment doors and setting the thing on the balance pan, one can weigh solid objects directly. After you shut the doors, the reading will be shown.

- When weighing liquids, powders, or granular materials, use the proper container. Zero the balance first, and then set the container on the pan. The sample should then be carefully added (either directly or by removing the container while making sure the control bar is untouchable), the doors should be closed, and the readout should be examined.

- Clean the balance well if any substances have spilled on it. Once your day’s weighing operations are complete, turn it off (by gently lowering the control bar.